Chicago Tunnel Company

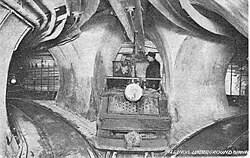

Under the streets of Chicago, pre 1906. | |

| Overview | |

|---|---|

| Headquarters | Chicago |

| Locale | Illinois |

| Dates of operation | 1906–1959 |

| Successor | abandoned |

| Technical | |

| Track gauge | 2 ft (610 mm) |

| Length | 60 miles (97 km) |

The Chicago Tunnel Company built a unique freight tunnel network under the downtown of the city of Chicago. It inspired the construction of the London Post Office Railway.[1]

History

The city of Chicago granted the newly formed Illinois Telephone and Telegraph company the rights to construct utility tunnels under the streets of Chicago in 1899 to carry its planned network of telephone cables. The tunnels were large enough to allow a narrow gauge railroad to operate below the telephone cables, and in 1903, the company renegotiated its franchise to allow the use of this railroad for freight and mail service. In early 1905, the system was taken over by the Illinois Tunnel Company. By this time, 26 miles (42 km) of a projected 60 miles (97 km) of tunnel had been completed.[2][3] The actual construction work was subcontracted to the Illinois Telephone Construction Company, under the management of George W. Jackson.[4][5][6]

By 1904, the first round of financing for tunnel system construction had largely been spent. A second round of financing was arranged by James Stillman of the National City Bank of New York City, with public support from E. H. Harriman, Jacob H. Schiff, and Patrick A. Valentine, all directors of that bank.[7] With this financing, the Chicago Subway Company, incorporated in New Jersey, became a new holding company for the tunnel system.[8][9]

The Chicago Warehouse and Terminal Company was an affiliate, formed in 1904 to construct and operate terminal facilities for interchanging freight with railroads and other carriers.[10]

By 1909, the cost of construction had bankrupted the Illinois Tunnel Company. By this time, it was estimated that $30,000,000 had been spent on building and operating the tunnel. The receiver's sale was completed in 1912, with the Chicago Tunnel Company, a wholly owned subsidiary of the Chicago Utilities Company, acquiring all assets of the former company and its affiliates, the Chicago Warehouse and Terminal Company and the Illinois Telephone and Telegraph Company. In 1913, the Chicago Tunnel Company agreed to sell its telephone operations to American Telephone and Telegraph Company, although regulatory approval delayed the actual sale until 1916. By 1920, all telephone cables had been removed from the tunnels.[11][12]

By 1914, about 60 miles (97 km) of tunnel had been constructed, typically 7.5 feet high and 6 feet wide, with 2 foot gauge track. 19 elevators connected the tunnel with customers, and 5 elevators served universal public stations where freight could be dropped off or picked up by the public. The railroad operated 132 electric locomotives, typically 30 to 50 horsepower each, and had 2,042 merchandise cars, 350 excavating cars and 235 coal and ash cars. In 1914, the tunnel company handled 609,320 tons of freight, 275,218 of which were merchandise. The remainder was presumably coal, ash and excavation debris.[13]

The Chicago Tunnel Company was declared bankrupt in 1956, and the network was closed and abandoned in the summer of 1959. Scrappers removed almost all of the overhead wire and elevators; locomotives and steel freight cars were removed and scrapped as well.

Construction

The standard tunnel was egg-shaped, 7.5 feet (228 cm) high and 6 feet (182 cm) wide, with tunnel walls 10 inches (25 cm) thick and a floor 14 inches (35 cm) thick. The tunnels were built through a layer of soft blue clay, and tunneling was done by cutting the clay with draw knives. Parts of the tunnel were pressurized to 10 psi during tunneling, while other parts were tunneled at atmospheric pressure. The tunnel was lined with coarse concrete and then waterproofed with a portland-cement limestone-dust plaster.[5][14]

The city asked that the tunnel be built no shallower than 22.5 feet (6.86 meters) below the pavement in order to allow room for a future streetcar subway.[15]

During construction, temporary 14 inch (35.5 cm) gauge tracks were laid. The 6 foot tunnel was wide enough for double tracks with this small size. 900 small cars ran on this track from the tunnel headings to hoists that removed the spoil to the surface or to points where the spoil could be transferred to 2-foot gauge cars for haulage to the Grant Park disposal station.[16] Tunneling work continued around the clock, 24 hours a day, completing an average of 2 miles (3 km) of tunnel per year per heading during the first few years of development[4][5]

The 2 foot (61 cm) gauge track was laid in the tunnels, using rails 4.25 inches (10.8 cm) high (56 pounds/yard or 27.8 kg/m). Crossties were not used. Instead, rails were mounted on chairs embedded in the concrete tunnel floor. Frogs and crossings were built on steel plates that were then embedded in the concrete floor.[4][5]

Curves in the tunnels were very tight. Mainline curves were as tight as 16 foot (4.9 meter) radius, and the grand unions under street intersections were built using a 20 foot (6.1 meter) radius. Grades in the tunnel system were limited to 1.75 percent, except for the lines up to the Grant Park disposal station, which climbed at a 12 percent grade.[16]

The tunnel, 40 feet below street level, was drained by 71 electric pumps. There was very little seepage into the tunnels, a natural consequence of excavation in clay, but any water that did find its way in was quickly pumped up to the sewers above. Ventilation was natural, relying primarily on the piston effect of trains pushing through the tunnels to circulate the air.[10]

While buidings with deep subbasements could connect directly to the tunnel, connections to surface level and shallow basements were by elevator shafts.[4][5] George W. Jackson, the contractor who built the tunnel system, received several patents related to building such shafts.[17][18]

Equipment

Motive Power

The first test trains were run a few years after the start of construction. Most of the tunnel system was operated using overhead lines and trolley poles for power.[19] Between 1903 and 1904, the Illinois Telephone Construction Company purchased 22 class L. M. locomotives from General Electric. These weighed 5 tons and had two 20-horsepower traction motors. Most of the engines used in the tunnels were standard mine haulage locomotives made by the Jeffrey Manufacturing Company. These weighed 6 tons and had two 18-horsepower traction motors each.[5][20][21] Commonwealth Edison provided the electric power at 250 volts.[22]

On the grades leading up from the tunnel to the Grant Park disposal station, the Morgan third-rail system sold by the Goodman Equipment Mfg. Co. of Chicago was used.[23] These locomotives used a central rack rail for both traction and power supply.[24][5][4][25] This system was also widely sold to the mining industry and was particularly valuable where mines had steep grades[26]. The Morgan locomotives were never intended for use outside the context of the grade to the Grant Park disposal station[5][4] and their use ceased with the abandonment of that trackage.

Between 1906 and 1908, the tunnel company purchased a number of Baldwin engines. One of these, number 508, was recovered from the tunnel leading to the Field Museum in 1996, when the rebuilding of the Outer Drive past the museum uncovered the old Grant Park Disposal Station elevator shaft. This engine is now in the collection of the Illinois Railway Museum.[27]

By 1914, the tunnel company was operating two gasoline fueled locomotives built by Baldwin Locomotive Works on the surface trackage in Grant Park.[28] These engines weighed 7 tons and were 12 feet (366 cm) long, 56 inches (142 cm) wide and 7.5 feet (229 cm) high. The 4-cylinder engines were coupled to the driving wheels through a jackshaft and side rods.[29] These machines had a 2-speed transmission with a top speed of 10 miles per hour (16 km/h).[30][31]

Freight Cars

The standard freight cars on the tunnel were 12.5 feet (381 cm) long and 47 inches (119 cm) wide, running on two 4-wheel trucks and designed to operate on curves with a 15 foot (4.6 meter) radius. Cars were equipped with MCB Couplers, and were of all steel and iron construction.

The tunnel bought hundreds of Bettendorf Flat cars that could be converted to gondolas and had a capacity of 30,000 pounds (15 tons).[4][32] Bettendorf's patents include several pertaining to cars that match this description.[33][34][35][36]

Ash and excavation debris removal cars were equipped with the Newman patent dump box[37] with a 3.5 cubic yard (2.7 cubic meter) capacity. Newman developed this dump box because the clay removed during tunnel excavation was so sticky that it was difficult to dump from conventional side-dump cars.[38] Additional cars were built by Kilbourne & Jacobs.[4]

Operation

Revenue service in the tunnels officially began on August 15, 1906, with a 2-mile 16-minute run. By that time, 45 miles (72 km) of track were in place, with connections to 4 railroads and a total of 40 customer connections. 67 locomotives and 400 freight cars were on hand.[39] In fact, coal delivery by subway began on October 13, 1905, when several carloads of coal were delivered from the Chicago and Alton Railroad coal chutes.[40]

In 1915, most tunnel operation occurred between 7 AM and 5 PM, with limited night operation primarily serving excavation spoil removal and coal and ash service. In a typical 10 hour work day, there were 500 to 600 train movements, all conducted under the authority of a telephone-based dispatching system.[10] Dial telephones were installed at every street intersection so that engineers could easily remain in contact with the dispatcher.[4] In 1914, the tunnel employed 568 people, including 116 motormen, 57 elevator men, 59 truckers, 74 clerks and 3 dispatchers.[41]

In 1929, it was estimated that the tunnels handled between 200 and 300 train movements a day, with 10 to 15 cars per train. At the time, the tunnel had 150 locomotives, 2693 merchandise cars, 151 coal cars and 400 excavation and ash cars.[42]

In 1954, the tunnel was carrying 500 carloads of freight and 400 carloads of cinders and debris daily. There were 83 locomotives, 1,609 freight cars, 55 trucks and 272 semi trailers on hand. Surface trucking was an important part of the business, required to reach customers located outside the loop. The workforce had declined considerably from the tunnel's heyday, with just 30 motormen operating the trains. The tunnel workforce was so dominated by attrition that someone with 25 years of experience in the tunnel was viewed as a newcomer.[43]

Merchandise

In 1914, the tunnel had direct connections for freight interchange (by elevator) with 26 railroads and 2 boat lines. In addition, there were 4 public tunnel stations where shippers could drop or pick up merchandise, and 36 industries had direct tunnel connections, including Chicago's big department stores, Marshall Field's, Carson Pirie Scott and Rothchild's. In 1913, the tunnel carried 544,071 carloads or 617,891 tons of merchandise. Of this, 231,585 carloads were sent from public stations, 177,743 carloads from industrial customers served by the tunnel, and 134,743 carloads from railroad freight terminals.[41]

The Illinois Tunnel Company built connections to post offices and passenger stations specifically for mail service[44][45]. Tunnel mail service began in September 1906 at a contracted rate of $172,600 per year. Within 6 months, it became apparent that the Tunnel Company was having difficulty with timely delivery, and the post office threatened to abrogate its contract.[46] Mail service through the tunnels was terminated at the end of the 2-year contract.

Coal

In 1914, 22 buildings had tunnel connections for coal delivery, including the First National Bank of Chicago, several hotels, Marshall Field's, City Hall and the County Building. A total of 16,414 carloads or 57,906 tons of coal were handled in 1913.[41]

The tunnel had 2 coal receiving stations in 1915 for loading coal onto tunnel trains. One was served by the Chicago and Eastern Illinois Railroad, the other by the Chicago and Alton Railroad. Surface railroad cars dumped coal into bins under the track, from which chutes led down to the tunnel. A tunnel car could be loaded with a full load of 3.5 tons of coal in 2 seconds.[10][47][48]

Coal was carried in side-dump cars, from which it was dumped into a hopper below each customer's boiler room. A conveyor then carried the coal up from the trackside hopper to the customer's boiler room.[47] The details of the latter connection depended on the depth of the building's basement. Chicago's new City building on the corner of Washington and LaSalle had a subbasement 38 feet below sidewalk level, so the tunnel connection was made by a 10 foot deep trench.[49] The Commercial National Bank's coal bins were under the sidewalk on Clark Street. There, coal was lifted from the tunnel by a vertical bucket conveyor running in a small shaft.[50]

Before the 1940s the tunnels were used to deliver coal to downtown buildings, and to remove ash or clinkers. Trucks began to siphon off significant amounts of business, however, and by the late 1940s, customers began to switch from coal to natural gas to heat their buildings. The ones that kept burning coal switched to delivery by truck because unloading from the surface was easier, and a complex conveyor system was not required.

Excavation Debris and Ashes

Early operation in the tunnels was dominated by removal of excavation debris from the tunnel itself, and once tunnel service reached various areas, several contractors found that it was less expensive to dump excavation debris down into tunnel trains than it was to haul it out through the congested streets of the Chicago Loop. As a result, excavation debris continued to make up a significant part of tunnel traffic after the tunnel system was completed. Ash from coal-fired furnaces was freely mixed with this stream of debris.[4][5][14]

In the early days of tunneling, excavation debris was hauled to the surface through small construction shafts, but by 1905, the inclined access tunnels up to the Grant Park disposal station were in place, and the vast majority of excavation debris and ash was hauled out to fill Grant Park. A derrick with a 65 foot boom picked the dump boxes off the cars and swung them out over the lake to dump the fill.[38]

The new Cook County Courthouse was among the construction sites that disposed of excavation debris through the tunnel system.[51]

In 1908, further dumping of refuse on the lake front was prohibited, and the Tunnel Company responded by building a new disposal station on the Chicago River. Here, elevators lifted tunnel cars to the surface where they were dumped into self-propelled catamaran "dump scows" with a capacity of 1000 cubic yards. The scows then took the debris out into the lake for dumping in deep water.[52] George W. Jackson, the Tunnel's chief engineer, filed a patent on a scow fitting this description.[53]

Filling on the lakefront began again in 1913, with the construction of a tunnel extension to a new disposal station on the lakeshore beyond what was then the south end of Grant Park. Here, twin elevators lifted the cars to the surface. Fill from this disposal station created the land under the the Field Museum of Natural History, Soldier Field and McCormick Place.[10][14].

In 1913, the tunnel system handled 51,685 carloads of excavation debris and 14,605 carloads of cinders and other refuse. Excavation debris and ash were billed per carload, so the tonnage is not available.[41] A 1929 estimate put the average combined excavation and ash traffic at 75,000 carloads per year.[42] Immense amounts of fill were hauled by tunnel to the lake during construction of Chicago's new main post office adjacent to Union Station in the early 1920's.[54]

Even though coal deliveries were made with trucks, it was still more efficient to remove ashes by tunnel.[citation needed] This basically left the company in the ash removal business for the last ten years of operation.

Secondary Businesses

The tunnel company had a curious secondary business, air conditioning by selling naturally cool tunnel air to theaters above the tunnels.[55] The McVickers, Rialto and 4 other theaters owned by the same company used tunnel air. They estimated that they used less than 1/3 the coal they would have used without the tunnel connection.[56] The tunnel air was a constant 55 degrees, year round.[10]

Disasters

- See also: Chicago Flood

In 1991 near the Kinzie Street bridge, a new set of pilings (collectively known as a "dolphin") were driven into the riverbed to prevent barges from bumping into the bridge. As the pillars were installed, a miscalculation was made that caused severe damage to the tunnel directly below the river.

In 1992, a cable television employee in the tunnel underneath the Chicago River videotaped mud and water oozing in where the bottom of the wooden pilings had penetrated the tunnel's roof. Official response was slow; no emergency measures were deemed necessary, and a formal bidding process began for the contract to repair the damage. However, in April a large hole formed in the roof of the affected tunnel, causing the river and large quantities of mud to pour in. In what became known as the Chicago Flood, the entire system was quickly flooded, as well as many skyscraper basements that were still connected to it, causing severe property damage and disrupting utility service throughout the Loop. Many businesses had had no idea that they were still connected to the tunnel complex, as the openings were boarded up, bricked up, or otherwise closed off—but not waterproofed. The accident shut down the entire downtown area for days, causing considerable economic losses. Insurance battles lasted for years, the central point being the definition of the accident, i.e., whether it was a "flood" or a "leak." Leaks were covered by insurance, while floods were not. Eventually it was classified a leak, which is why many residents still call it the "Great Chicago Leak."[citation needed]

At that point, government agencies belatedly responded. The leak was stopped and the tunnels were emptied within days at great cost. The tunnels are still used for power and communication cables.[citation needed] They have been popular with urban exploration groups who would sometimes sneak in to have a look around, but after a terrorism scare in the early 2000s involving a deranged former Chicago Urban Exploration member, all access to the tunnels has been secured.[57]

On October 14, 2009, workers pumping concrete into the tunnel under the Kennedy expressway caused the roadway to buckle, shutting down all but one lane of I-90 West.

References

- ^ Unofficial MailRail Website

- ^ George W. Jackson, Freight Tunnels in Chicago, The Methodist Magazine and Review, vol. LXII, No. 3 (Sept. 1905);page 280.

- ^ George W. Jackson, Freight Tunnels in Chicago, The Independent, Vol LVII, No. 2918 (Nov. 3, 1904);page 1018. Note: Illustrated.

- ^ a b c d e f g h i j Frank C. Perkins, An Electric Underground Freight Railway, Modern Machinery, Vol XVIII, No. 6 (Dec. 1905); page 321. Note: Illustrated; this article is almost identical to Jackson's 1905 article.

- ^ a b c d e f g h i George W. Jackson, The Chicago Freight Subway, The Americana -- A Universal Reference Library, Volume 4, Scientific American, 1905; page 345. Note: This article is almost word for word identical to Perkins' 1905 article.

- ^ George W. Jackson Dies, New York Times, Feb. 6, 1922; page 10. Note: The date of death was Feb. 2, 1922.

- ^ Chicago's Traction Project, The Technical World, Vol. 2, No. 5; page 625.

- ^ $50,000,000 Company Gets Chicago Subways, New York Times, Tues. Nov., 22, 1904; page 12.

- ^ Certificate of Incorporation of Chicago Subway Company, quoted in Thomas Covington, A Manual of Corporate Organization The Ronald Press, 1908; page 303.

- ^ a b c d e f The Chicago Tunnel, The Traffic World Vol. XVI, No. 10, (Sept. 4, 1915); page 587. Note: Illustrated.

- ^ In the Matter of the Petetion of the Chicago Tunnel Company ... State Public Utilities Commission of Illinois -- Opinions and Orders for the Year Ending Sept. 30, 1916, Vol III, 1916; page 83.

- ^ Chicago Utilities Co., Burnham's Manual of Mid-Western Securities, John Burnham and Company, 1921; page 189

- ^ Edward G Ward, ed., Chapger VII, The Switching Service, Part 15. ... as Afected by Tunnel Service (at Chicago), The Traffic Library -- Special Freight Services -- Allowances and Privileges, Part II, The American Commerce Association, 1916; page 216.

- ^ a b c Methods and Progress of Driving Freight Tunnel Extension in Chicago, Engineering and Contracting, Vol. 39, Part 2, No 22. (May 28, 1913); page 620.

- ^ Henry M. Hyde, People or Freight Underground, The Technical World, Vol. 1, No. 5 (July 1904); page 530. Note: Illustrated.

- ^ a b Goods Subways in Chicago, The Tramway and Railway World, Vol. XVII, April 6, 1905; Page 324.

- ^ George W. Jackson, Art of Constructing Lining-Walls for Shafts Excavated in the Earth, U.S. Patent 835,159, Nov. 6, 1906.

- ^ George W. Jackson, Lining-Wall for Shafts, U.S. Patent 1,009,312, Nov. 21, 1911.

- ^ William A. Loudon, Trolley-Stand, U.S. Patent 885,063, Apr. 21, 1908.

- ^ Thompson-Houston Electric Co. vs. Illinois Telephone Construction Co. et al, The Federal Reporter, Vol. 152 ( May-June 1907), West Publishing Co.; page 631.

- ^ Jeffrey Electric Mine Locomotives, Jeffrey Elevating-Conveying, Power Transmission Machinery, Coal Mine Equipments General Catalog No. 82, Jeffrey Mfg. Co. 1912; page 529.

- ^ 179-Chicago Tunnel Co.,McGraw Electric Railway List, McGraw-Hill, Feb. 1918; page 32.

- ^ Edmund C. Morgan, Electric-Railway System U. S. Patent 659,178, Oct. 2, 1900. This patent describes the locomotive.

- ^ Edmund C. Morgan, Combined Third and Traction Rail for Electric Railways, U. S. Patent 753,803, Mar. 1, 1904. Note: The rail was mounted in the tunnel as shown in Fig. 2.

- ^ Third- or Rack-Rail Haulage, Mining and Minerals, May 1904; page 513.

- ^ J. J. Rutledge, Recent Improvements in Coal Mining in Illinois, Mining Magazine Vol. XIII, No. 3 (March 1906); page 186.

- ^ Les Ascher and Dave Diamond, IRM Goes Underground, Rail and Wire, Issue 162 (Nov. 1996).

- ^ The Baldwin Locomotive Works -- Gasoline Locomotives for Industrial and Contractors Service, The Bulletin of the General Contractors Association, Vol. 5, No. 2 (Feb. 1914); page 100. Note: Illustrated.

- ^ Tunnel Gasoline Locomotive in Chicago, Gas Power, Vol. 11, No. 10 (April 1914); page 62. Note: Illustrated.

- ^ Charles McShane, Gasoline Locomotives, The Locomotive Up To Date, Griffin & Winters, Chicago, 1921; page 700.

- ^ Internal Combustion Locomotives, The Baldwin Locomotive Works, Record No. 95, 1919. Note: A Tunnel Co. Loco is shown on page 32.

- ^ Supply Trade Notes, Railway Master Mechanic, Vol. XXXI, No 3 (March 1907);page 107.

- ^ William P. Bettendorf, Box Car Construction, U.S. Patent 1,036,786, Aug. 27, 1912.

- ^ William P. Bettendorf, Underframe for Dumping-Cars, U.S. Patent 1,039,638, Sept. 24, 1912.

- ^ William P. Bettendorf, Underframe for Dumping-Cars, U.S. Patent 1,062,689, May 27, 1913.

- ^ William P. Bettendorf, Railway Car Truck, U.S. Patent 1,032,348, July 9, 1912.

- ^ William J. Newman, Dumping Apparatus, U. S. Patent 731,118, June 16, 1903.

- ^ a b Halbert Powers Gillette, Dumping Cars with Derricks, Handbook of Earth Excavation McGraw Hill, 1920; page 382.

- ^ Electric Freight Service in Chicago Tunnels, The Electrical Age, Vol. XXXVII, No. 4 (Oct. 1906); page 320.

- ^ Freight on Chicago Subway, New York Times, Oct. 15, 1905; page 14.

- ^ a b c d Thirty-Sixth Day, Exhibits A to M, 3, Five Per Cent Case, Vol 3, Interstate Commerce Commission, 1914; pages 2572-2593.

- ^ a b M. L. Allen, Beating Chicago's Traffic Bogey, The Ohio State Engineer, Vol. 12, No. 5 (March 1929); page 6. Note: Illustrated.

- ^ Footnote Under Chicago, The Rotarian, Vol LXXXVI, No. 2 (Feb. 1955); page 98.

- ^ S. F. Joor, Elevating and Conveying Machinery, Journal of the Western Society of Engineers, Vol. XI, No. 2, (Mar.-Apr., 1906); page 203-204 and 194-195.

- ^ Frank C. Perkins, Electric Mail Transportation Through Chicago Subway, The Railroad Trainman, Vol XXV, No. 11, Nov. 1908; page 925. Note: Illustrated.

- ^ H. G. Seger, letter to James T. McCleary, Apr. 29, 1908; in Hearings on the Bill (H.R. 18347) Making Appropriations for the Service of the Post-Office Department for the Fiscal Year Ending June 30, 1909, Government Printing Office, 1908; page 41.

- ^ a b The Coal and Freight Tunnels of Chicago, Compressed Air, Vol. XIII, No. 8 (Aug. 1908); page 4989.

- ^ Coal Handling in the Chicago Subway, Minutes of Proceedings of the Institution of Civil Engineers, Vol. CLXVI (1906); page 437.

- ^ Statistics of the Construction of Chicago's Big Municipal Building, The Architectural Record, Vol XXXI, No. IV, Apr. 1912; pages 371,

- ^ G. F. Gebhardt, Steam Power Plant Engineering, Wiley, 1910; page 189.

- ^ Halbert Powers Gillette, Concrete Construction, Myron C. Clark, 1908; page 162.

- ^ Frank C. Perkins, The Chicago Underground Railway System of Refuse Disposal, Municipal Engineering, Volume XXXV, No. 1 (July 1908); page 21.

- ^ George W. Jackson, Scow for Transporting Gravel, U.S. Patent 1,047,233, Dec. 17, 1912.

- ^ R. F. Imler, Huge Steel Truss Placed in Chicago U.S. Mail Terminal, Engineering World, Vol. 19, No 5 (Nov. 1921); page 313.

- ^ Thomas R. Wilson, A Ventilation Paradox, The Heating and Ventilating Magazine, Vol. XV, No. 10 (Oct 1918); page 42. Note: Illustrated.

- ^ Tunnel Air Saves Coal, Domestic Engineering, Vol. 101, No. 6 (Nov. 11, 1922); page 254.

- ^ "Man allegedly stored cyanide in Chicago subway". CNN. 2002-03-12. Retrieved 2007-12-28.

- Moffat, Bruce (1982). Forty Feet Below: The Story of Chicago's Freight Tunnels. Interurban Press. ISBN 0-916374-54-8.

- Moffat, Bruce (2002). The Chicago tunnel story: exploring the railroad "forty feet below". Interurban Press. ISBN 0915348357.

External links

- Chicago Tunnel Company Railroad Home Page

- Frédéric Delaitre's Lost Subways

- Freight Tunnel Flood

- Chicago Urban Exploration Mission 1

- Chicago Urban Exploration Mission 2