Japanese sword

- This article is about the Japanese sword. For the motorcycle, see Suzuki Katana. For the use of the katana in fiction, see Katana (Fiction).

The katana (刀) is the Japanese backsword or longsword (大刀 daitō) of the type specifically in use after the 1400s (following the use of the tachi), although in Japanese this word serves generically as a catch-all word for sword. Katana (pronounced [kah-tah-nah]) is the kun'yomi (Japanese reading) of the kanji 刀 ; the on'yomi (Chinese reading) is tō. While the word has no separate plural form in Japanese, it has been adopted as a loan word by the English language, where it is commonly pluralised as katanas.

The term "katana" refers to a specific type of curved, single-edged sword traditionally used by the Japanese samurai (buke retainers to the daimyo). The weapon was typically paired with the wakizashi or shoto, a similarly made but shorter sword both worn by the members of the buke (bushi) warrior class. It could also be worn with the tantō, an even smaller similarly shaped blade. The two weapons together were called the daisho which literally means big-small, and represented the social power and personal honor of the samurai. The long blade was used for open combat, while the shorter blade was considered a side arm, more suited for stabbing, close combat (such as indoors), and seppuku, a form of ritual suicide. The scabbard for a katana is referred to as a saya, and the handguard piece, often intricately designed as and individual work of art — especially in later years of the Edo period — was called the tsuba. Other aspects of the koshirae (mountings), such as the menuki (decorative grip swells), habaki (blade collar and scabbard wedge), fuchi and kashira (handle collar and cap), kozuka (small utility knife handle), kogai (decorative skewer-like implement), saya lacquer, and tsuka-ito (professional handle wrap), received similar levels of artistry.

The katana is primarily used for cutting, although its curvature is generally gentle enough to allow for effective thrusting as well. Though it is intended for and was predominantly used with a two-handed grip, many extant historical Japanese sword arts include at least one or two single-handed techniques. It is traditionally worn edge up. While the practical arts for using the sword for its original purpose are now somewhat obsolete, kenjutsu and iaijutsu have turned into gendai budo — modern martial arts for a modern time. The art of drawing the katana and attacking one's enemies is iaido (also known as battōjutsu/battodo), and kendo is an art of fencing with a shinai (bamboo sword) protected by helmet and armour. Old koryu sword schools do still exist (for example, Kashima Shinto-ryu, Kashima Shin-ryu, and Tenshin Shoden Katori Shinto-ryu, among others). Perhaps one of the more famous types of Japanese fencing was "niten-ichi-ryu" or the use of both the katana and wakizashi in tandem; a technique most famously used by Miyamoto Musashi, though the extensive popularization of this technique in anime, literature, and pop culture has skewed modern perspective on its importance and prevalence.

The sword in Japanese society

The sword was considered the soul of the samurai. Although other weapons waxed and waned in popularity throughout history, the sword remained a constant. Although spears have survived since as far back as the 8th century AD, it was not until the large scale wars of the Onin period towards the end of the fifteenth century that the straight bladed spear, the yari, vied with the sword for the most popular weapon. The Japanese pinned an extraordinary amount of value on the sword. For much of Japan's history, only samurai were even allowed to carry swords, and a peasant carrying a sword was enough reason to kill the peasant and take the sword after a prohibition was issued in early Edo period. Ronin, needing money, would sometimes be forced to sell their swords, further adding to their highly dishonorable, sometimes vagabond status in Japanese society. They would be "soulless" in the eyes of a samurai.

Much of early Japanese culture revolved around swords. Elaborate methods for carrying, cleaning, storing, sharpening (or not sharpening), and wielding the sword evolved from era to era.

For example, a samurai entering someone's house might consider how to place his sheathed sword as he knelt. Positioning his sword for an easy draw implied suspicion or aggression; thus, whether he placed it on his right or left side, and whether the blade was placed curving away or towards him, was an important point of etiquette. As for the host, his long-sword was generally stored above the wakizashi on a rack called a katana-kake, curving upwards; in the manner it was worn, with the omote side showing (tsuka or handle pointing left). The Tachi on the other hand, had a stand, the tsuka was set in a groove at the base and the saya pointed upwards set in a notch at the top with the cutting edge down, again in the manner it was worn.

However, until the Edo period most samurai did not use their sword as a primary weapon; they used a bow first, a spear next, and then the sword. Drawing the sword was like letting the soul blaze free when down to the last straw. To have fought until nothing but a surrender is possible was described as Ken ore, ya mo tsuki, (lit. "with swords broken and without an arrow") used as a proverb.

History of the Japanese sword

In the 6th century BC the legendary Emperor Jimmu conquered much of Japan. At the same time, the Japanese learned the art of swordmaking from Chinese smiths. Early swords were in the style of Chinese swords, straight and single or double-edged.

One of the oldest known forms of kenjutsu dates the Kofun era (3rd and 4th centuries). The style, called Kashima no Tachi (鹿島の太刀), was created at the Kashima Shrine (in Ibaraki Prefecture). In the Heian Period (8th to 11th centuries) we see the development of sword-making, through techniques brought from the Russia and North part of Japan Hokkaido in those days Ainu's territory. The Ainu people used Warabite-tou(蕨手刀) Warabite sword and this sword influenced the Katana. According to legend, the Japanese sword was invented by a smith named 'Amakuni' in AD 700, along with the folded steel process. Among other modifications, the katana becomes single-edged, and better suited for slashing. This is also reflected in the styles of kenjutsu created during this period. From the Kashima shrine's Kashima no Tachi sprang the Kantō-nanaryū (関東七流 - also known as the Kashima-nanaryū 鹿島七流). In the same period, the Kyō-hachiryū (京八流) was created in the Kurama mountain (in Kyoto).

By the twelfth century, civil war erupted after a long period of decadence. For five centuries, Japan had its own dark ages, marked by continuous, brutal wars. The War of Onin (1467-1477) revolutionized Japanese armour.

During the Muromachi period, bloody wars were the norm, but the indolent shogunates also put a high value on art and culture, so the islands did not descend into barbarism. While many good swords were made during this period, the vast need for swords caused smiths to switch to production line methods. Furthermore, the ferocity of the fighting caused the highly artistic techniques of the Kamakura period (known as the Golden Age of Swordmaking) to be abandoned in favor of more utilitarian and disposable weapons. The export of katana reached its height during Muromachi period with the total of at least 200,000 katana being shipped to the Ming dynasty in official trades. The (ultimately failed) rationale behind this was to attempt to soak up the production of Japanese weapons and make it harder for pirates in the area to arm. As time progressed, the craft decayed under the needs listed above, and the introduction of guns, as a decisive force on the battlefield.

The famous failed invasion of Japan by the Mongols marked another point of evolution for the Japanese sword. Kokan Nagayama states that the "Japanese warriors had never before encountered such an enemy (the Mongols), who was protected by leather armor and wielded a very stout sword -- clearly superior to theirs -- in a unique style of fighting." He added that certain Japanese swordsmiths started to adopt thinner and simpler temper lines due to their belief that " blades with wide temper lines reaching near to the ridge line look gorgeous, but tend to break."[1] Unfortunately, Mr Nagayama did not quote the Japanese historical references from which he derived his comments on the superiority of the Mongol (i.e. continental Chinese, Korean and other makes) sword over the Japanese sword. Other Japanese scholars had also highlighted that certain Japanese swordsmiths of this period began to make blades with thicker backs and bigger points, as a counter-response to the Mongol threat.

In times of peace, swordsmiths had time and the inclination to return to the making of refined and artistic blades, and the beginning of the Momoyama period saw the return of high quality creations. As the techniques of the ancient smiths had been lost during the previous period of war, these swords were called shinto, literally 'new swords.' This gave the obvious name to the older blades as koto, 'old swords.' The blades that predated the curved blades introduced around 987AD were referred to as 'jokoto' or ancient swords. As the Edo period progressed, there came a decline in quality once again, for a variety of reasons, including the evolution of the samurai class into bureaucrats and policemen; other related arts did move forward from time to time, leading to beautiful engravings and decorations for weapons. The addition of these engravings known as 'horimono' were originally for religious reasons, and were simple and tasteful. It is often considered that the more complex work found on many shinto swords then is a corruption, where form no longer strictly follows function and thereby no longer achieves a pure form of beauty.

Under the isolationist Tokugawa Shogunate, guns and gunpowder were increasingly restricted and removed from circulation. By the middle of the eighteenth century, most young Japanese had never seen a gun, let alone actually seen one fired.

Towards the end of this period, swordmaking had fallen to another low, and due to the efforts of the master swordsmith Munetsugu at the turn of the 19th century, artistic merit once again returned to the craft. Munetsugu published opinions that the arts and techniques of the shinto swords were inferior to the koto blades, and that research should be made by all swordsmiths in the land to rediscover the lost techniques. Munetsugu travelled the land teaching what he knew to all who would listen, and swordsmiths rallied to his cause and ushered in a second renaissance in Japanese sword smithing. With the discarding of the Shinto style, and the re-introduction of old and rediscovered techniques, the swords of this time were now called 'shinshinto' meaning 'new-new swords.'

Japan remained in stasis until Matthew Perry's arrival in 1853 and the subsequent Convention of Kanagawa forcibly reintroduced Japan to the outside world; the rapid modernization of the Meiji Restoration soon followed.

The Haitorei edict in 1876 all but banned carrying swords and guns on streets, making samurai less distinguishable from commoners. Possession itself was not prohibited, so many katana were simply stashed away. Overnight, the market for swords died, and many swordsmiths were left without a trade to pursue, and valuable skills were lost. In time, the need to arm soldiers with swords was perceived again and over the decades at the beginning of the 20th century swordsmiths again found work. These swords, known as 'gunto', are often very low in quality with many being oil tempered or simply stamped out of steel and given a serial number rather than a chiseled signature.

Katana remained in use in some occupations, police sometimes using katana not only to catch criminals but to defend themselves from criminals who could be armed with katana as well. At the same time, Kendo was incorporated into police training so that police officers would have at least the minimal training necessary to properly use one.

Though this was a dark time for the katana, the craft was kept alive through the efforts of a few individuals, and notably the Gassan line of smiths who were employed as Imperial Artisans. These smiths, Gassan Sadakazu and Gassan Sadakatsu were kept busy producing fine works that stand with the best of the older blades for the Emperor and other high ranking officials. The students of Gassan Sadakatsu went on to be designated Intangible Cultural Assets, or more commonly known as Living National Treasures, as they embodied knowledge that was considered to be fundamentally important to the Japanese identity. In 1934 the Japanese government issued a military specification for the shin gunto "new army sword" the first version of which was referred to as a "Type 94 katana", and many machine- and handcrafted swords used in World War II conformed to this and later shin gunto specifications.

Under the United States occupation at the end of World War II all armed forces were disbanded and, except under several permits issued by police and municipal government, production of katana with edges was banned. This ban would be later overturned through the personal appeal of Dr. Homma Junji to General Douglas MacArthur. During their meeting, Dr. Homma produced blades from the various periods of Japanese history and General MacArthur was a quick student, being able to identify very quickly what blades held artistic merit and which could be considered purely weapons. As a result of this meeting, the general ban was amended so that the weapon grade gunto would be destroyed and swords of artistic merit could be owned and preserved. Even so, many katana were sold to American soldiers who had money to spend at a bargain price. Some were simply stolen, while others remained stashed away.

Due to this disarmament, as of 1958 there were more Japanese swords in America than in Japan: American soldiers would return from the Orient with piles of swords, often as many as they could carry. The vast majority of these 1,000,000 or more swords were gunto, but there were still a sizable number of koto, shinto and shin-shinto.

Swordsmiths had been increasingly turning to producing civilian goods after the Edo period but this disarmament and subsequent regulations almost put an end to the production of katana. A few smiths did continue their trade, and Dr. Homma went on to be a founding figure of the Nihon Bijitsu Hozon Token Kai, the 'Society for the Preservation of Art Swords', who made it their mission to preserve the old techniques and blades. With the efforts of other like minded individuals, the katana has arisen from its darkest day and many swordsmiths have continued the work begun by Munetsugu, re-discovering the old techniques and making the art swords produced by today's best smiths as good as many of the blades of old.

Some katana have been used in modern-day armed robberies. [1] However it is likely that most of these katana are sword like objects, as a basic, properly constructed katana is comparative in price to an inexpensive handgun.

Classification of Japanese swords

Classification by length

All Japanese swords are manufactured according to this method and are somewhat similar in appearance. What generally differentiates the different swords is their length. Japanese swords are measured in units of shaku (1 shaku = approximately 30.3 centimeters or 11.93 inches; from 1891 the shaku has been defined as exactly 10/33 metres, but older data may vary slightly from this value). For more precise measurement, "sun", "bu", and "rin" (one-tenth, one-hundredth, and one-thousandth of a shaku respectively) may be used.

- A blade shorter than 1 shaku (30 cm) is considered a tanto (knife).

- A blade longer than 1 shaku but less than 2 (30–61 cm) is considered a shoto (short sword) and included the wakizashi and kodachi.

- A blade longer than 2 shaku (61 cm) is considered a daito, or long sword. This is the category 'katana' fall into. However, the term 'katana' is often misapplied: a sword is only a katana if it is worn with cutting edge up through a belt-sash called an obi (these 'katana' averaged 65 cm in blade length). If it is suspended by cords from a belt, it is called 'tachi' (average blade length of 75 cm) the tachi is worn cutting edge down.

- Abnormally long blades (longer than 3 shaku or 90cm), usually carried across the back, are called ōdachi or nodachi. 'ōdachi' is also sometimes used as a synonym for katana.

A chisa-katana is simply a shorter katana. A katana was longer than two shaku in length. However, a chisa-katana is longer than the wakizashi, which was between one and two shaku in length. Chisa-katana were not common weapons since usually a katana was made for a taller person or a wakizashi for a shorter person. The most common reference to a chisakatana is a shorter katana that does not have a companion blade. They were most commonly made in the Buke-Zukuri mounting.

While the length is a general guidline to how long the katana, wakizashi and tanto are. Many schools have had their own ideas of how long a katana ect should be. There was a time when you could tell what swordschool a person belonged to just by the length of their katana.

Classification by schools and provinces

Japanese swords can be traced back to one of several provinces, each of which had its own school, traditions and 'trademarks' - e.g., the swords from Mino province were "from the start famous for their sharpness".[2] These traditions and provinces are as follows:

| Soshu School | Yamato School | Bizen School |

| Yamashiro School | Mino School (e.g. kanenobu) | Wakimono School |

Classification by date of manufacture

| Before 987: | Some straight 'chokuto' or 'jokoto' and others with unusual shapes. |

| 987 - 1597: | A 'koto': these are considered the pinnacle of Japanese swordcraft. Early models had uneven curves with the deepest part of the curve at the hilt. As eras changed the center of the curve tended to move up the blade. |

| 1597 - 1760: | Known as 'shinto', or 'new sword'. These are considered inferior to most koto, and generally coincide with a degradation in manufacturing skills. |

| 1761 - 1876: | If made in koto style, these are called 'shinshinto', or 'new revival swords' (literally 'new new swords'). These are considered superior to most shinto, but worse than koto. |

| 1876+: | Post-Haitorei Edict. Any mass-produced blade is derisively called 'gunto'. These often look like Western cavalry sabers rather than katana, although most are just like katana, with many mass-produced and in general slightly shorter than blades of the shinto and shinshinto periods. |

Classification by mode of wear

| Before 1500: | Most swords worn suspended from cords on a belt, blade-down. This style is called 'jindachi-zukuri', and all daito worn in this fashion are 'tachi'. |

| 1500 - 1867: | Almost all swords are worn through a sash, paired with a smaller blade. Both blades are blade-up. This style is called 'buke-zukuri', and all daito worn in this fashion are 'katana'. |

| 1867+: | Due to restrictions and/or the deconstruction of the Samurai class, most blades are worn jindachi-zukuri style, like Western navy officers. Recently (1953+) there is a resurgence in buke-zukuri style, permitted only for demonstration purposes. |

Notes

- Swords designed specifically to be tachi are generally koto rather than shinto, so they are generally better manufactured and more elaborately decorated. However, these are still katana if worn in modern 'buke-zukuri' style. The signature almost always appears on the side facing away from the body when the blade is worn, so it is possible to discern the smith's intention for the blade in this manner.

- There are many varieties of wooden practice blades, including those made out of wood (bokken) and those made out of bamboo (often used for kendo practice, usually referred to as shinai).

- Most of the various kinds of spears could come with blades made in the same style as the Japanese sword. The two main types are 'naginata', similar to a halberd in use, and a 'yari' which is more traditionally spear like. Although largely overlooked in Western literature, until the Kamakura period spears were the first resort of any samurai and most peasants, and the blades on the samurai spears were often of extremely high quality. However, despite this, the sword was still considered the soul of the samurai, not the spear.

- The 'soul of the samurai' concept has its roots in the early Tokugawa Shogunate. While there has always been reverence for the sword, the official line of it being the 'soul' comes from a need of the Shogunate to provide high value gifts to retainers and noblemen. In older days, these gifts would be of land, but at the time of the Shogunate land was a scarce commodity. It is considered that this angle of the sword was played up by those in power in order to replace land in the role of a gift of great honor. It became traditional that Daimyo and the Shogun, and the members of their families, would exchange gifts of swords when meeting together or for special occasions such as weddings and births. As such, the art of 'kantei' (the ability to judge a sword for period, maker, and quality) became important, as this allowed specialists to appraise a blade and so place its value. Older swords by honored makers would then be reserved for very special gifts, in particular to the Shogun and his family or from the Shogun to show very special merit.

Manufacturing

Japanese swords and other edged weapons are manufactured by the Chinese method of repeatedly heating, folding and hammering the metal. This practice became popular from use of highly impure metals, stemming from the low temperature yielded in the smelting at that time and place. In order to counter this, and to homogenize the carbon content of the blades (giving some blades characteristic folding patterns), the folding was developed (for comparison see pattern welding), and found to be quite effective, though labour intensive.

The distinctive curvature of the katana is partly due to a process of differential quenching. The back of the sword is coated with clay, insulating it and so causing it to cool slower than the edge when the blade is quenched. This produces a blade with a hard martensite edge and softer pearlite back, allowing it to be resilient and yet retain a good cutting edge.

This process also makes the edge of the blade contract less than the back when cooling down, something that aids the smith in establishing the curvature of the blade.

While some people believe that katana and wakizashi were constructed alike, this was not always the case. They were often forged with different profiles, different blade thicknesses, and varying amounts of niku. Wakizashi were also not simply a 'scaled down' katana, they were often forged in hira-zukuri or other such forms, which were very rare on katana.

On a related note, the Daisho (pair of swords) was not always forged together. If a samurai was able to afford a daisho, it was often composed of whichever two swords could be conveniently acquired, sometimes by different smiths and in different styles. Even when a daisho contained a pair of blades by the same smith, they were not always forged as a pair or mounted as one. "True" daisho, containing a pair of blades that were made as a pair, mounted as a pair, and owned/worn as a pair, are therefore uncommon and considered highly valuable - especially if they still retain their original mountings (as opposed to later mountings, even if the later mounts are made as a pair).

Japanese swords are fairly uncommon today, but not so rare that genuine antiques cannot be acquired - from reliable sources at significant expense, of course. Modern katana and wakizashi are only made by the few licenced practitioners that still practice making these crafted weapons today. Most of the "type 98 katanas" from World War II do not exist today, as well as the older versions.

Manufacturing processes are described in greater detail in following subsections.

Composition

Traditional Japanese steel is popularly considered to be one of the best for creating swords, but the true reasons for this are artistic and not functional - contemporary western steels were and most modern steels are actually superior in strength and purity. The total composition varied from smith to smith and lode to lode of ore.

One more modern formula (from World War II):

| Mineral composition: | |

| Iron | 98.12% to 95.22% |

| Carbon | 3.00% to 0.10% |

| Copper | 1.54% |

| Manganese | 0.11% |

| Tungsten | 0.05% |

| Molybdenum | 0.04% |

| Titanium | 0.02% |

| Silicon | Varying amount |

| Miscellaneous compounds | Trace amount |

The high percentage of carbon gave the blade strength while the silicon increased the flexibility of the blade as well as its ability to withstand stress.

Construction

The forging of a Japanese blade typically took hours or days, and was considered a sacred art. As with many complex endeavors, rather than a single craftsman, several artists were involved. There was a smith to forge the rough shape, often a second smith (apprentice) to fold the metal, a specialist polisher, and even a specialist for the edge itself. Often, there were sheath, hilt, and tsuba (handguard) specialists as well.

The most famous part of the manufacturing process was the folding of the steel. Steel was repeatedly 'folded', bent over itself and hammered flat. This did several things:

- It eliminated any bubbles in the metal.

- It homogenized the metal, spreading the elements (such as carbon) evenly throughout - increasing the effective strength by decreasing the number of potential weak points.

- It created layers, by continuously decarburizing the surface and bringing the surface into the blade's interior, which gives the swords their unique and beautiful grain. Despite widespread popular belief that the layered structure provides enhanced mechanical properties of the steel, this is completely false. Layers act as weld points which can only serve to weaken the integrity of the blade. (Bulat steel layering is an entirely different chemical effect, and does not apply to blades made in the Japanese fashion.)

- It burned off many impurities, again helping to overcome the Japanese steel's poor quality and purify/strengthen the sword.

Contrary to popular belief, continued folding will not create a "super-strong" blade; once impurities are burnt off and the carbon content homogenized, further folding offers little benefit and will gradually burn out the carbon, leading eventually to a softer steel less able to hold an edge. The number of folds varied from sword to sword, but those with more than about a dozen folds are uncommon, and authentic swords with more than two dozen folds are completely unknown. It should be noted that a blade folded 12 times will have more than 4,000 'layers' underneath the initial blade to begin with, and that 20 folds would produce a blade with over a million layers. Beyond this number, the molecular structure of the blade is such that further folding would most likely serve no further purpose. Even before this point, more layers does not equal a better sword; though folding does burn off impurities and homogenize the blade, a very even and clean composition is obtained early in the process, and control of carbon content has a much greater effect on the blade's functionality. Thus, the best results were usually obtained at 8-10 folds.

Generally, swords were created with the grain of the blade (called 'hada') running down the blade like the grain on a plank of wood. Straight grains were called 'masame-hada', wood-like grain "itame," wood-burl grain "mokume," and concentric wavy grain (an uncommon feature seen almost exclusively in the Gassan school) 'ayasugi-hada'. The difference between the three normal grain types (masame-, itame-, and mokume-hada) is one of cutting a tree perpendicular to its direction of growth (mokume) at an angle (itame) or along the grain (masame), the angle causing the "stretched" pattern. The blades that were considered the most robust, reliable, and of highest quality were those made in the Mino tradition, especially those of Magoroku Kanemoto. Bizen tradition, which specialized in mokume, and some schools of Yamato tradition were also considered strong warrior's weapons.

One of the core philosophies of the Japanese sword is that it has a single edge. This means that the rear of the sword can be used to reinforce the edge, and the Japanese took full advantage of this fact. When finished, the steel is not quenched or tempered in the conventional European fashion. Steel’s exact flex and strength vary dramatically with heat variation, and depending on how hot it gets and how fast it cools, the steel has vastly different properties. If steel cools quickly, from a hot temperature, it becomes martensite, which is very hard but brittle. Slower, from a lower temperature, and it becomes pearlite, which has significantly more flex but doesn’t hold an edge. To control the cooling, the sword is heated and painted with layers of sticky clay. A thin layer on the edge of the sword ensures quick cooling, but not so fast as to crack the sword steel (this makes the actual edge of the sword extremely hard martensite). A thicker layer of mud on the rest of the blade causes slower cooling, and softer steel, giving the blade the flex it needs (this makes the rear and inside of the sword into pearlite). When the application is finished, the sword is quenched and hardens correctly.

Eventually the Japanese began to experiment with using different types of steel in different parts of the sword. Examples are shown below:

The vast majority of 'good' katana and wakazashi are of 'wariba-gitae' type, but the more complex models allow for parrying without fear of damaging the side of the blade. The last generally accepted model, the 'shiho-zume-gitae', is quite rare, but added a rear support.

The 'makuri-gitae' is made using two steels, one folded more times than the other, or of a lesser carbon content. When both sections have been folded adequately, they are bent into a 'U' shape and the softer piece is inserted into the harder piece, at which point they are hammered out into a long blade shape. By the end of the process, the two pieces of steel are fused together, but retain their differences in hardness. To make han-sanmai-awase-gitae or shiho-zume-gitae, pieces of hard steel are then added to the outside of the blade in a similar fashion.

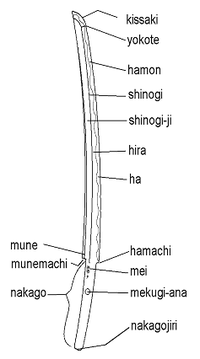

Anatomy of the katana

Each blade has a unique profile, depending on the smith, the construction method, and a bit of luck. The most prominent is the middle ridge, or 'shinogi'. In the earlier picture, the examples were flat to the shinogi, then tapering to the blade. However, swords could narrow down to the shinogi, then narrow further to the blade, or even expand outward towards the shinogi then shrink to the blade (producing a trapezoidal shape). A flat or narrowing shinogi is called 'shinogi-hikushi', whereas a 'fat' blade is called a 'shinogi-takushi'.

The shinogi can be placed near the back of the blade for a longer, sharper, more fragile tip or a more moderate shinogi near the center of the blade.

The sword also has an exact tip shape, which is considered an extremely important characteristic: the tip can be long (ô-kissaki), medium (chû-kissaki), short (ko-kissaki), or even hooked backwards (ikuri-ô-kissaki). In addition, whether the front edge of the tip is more curved (fukura-tsuku) or (relatively) straight (fukura-kareru) is also important.

It is important to point out that the kissaki (point) is not a "chisel-like" point, nor is the Western knife interpretation of a "tanto point" at all correct or Japanese. Such western knife blades feature a straight, linearly-sloped point whose sole advantage is being easy to grind and which only bears a superficial similarity to traditional Japanese kissaki. Kissaki have a curved profile, and smooth three-dimensional curvature across their surface towards the edge - though they are bounded by a straight line called the yokote and have crisp definition at all their edges.

A hole is drilled into the tang (nagako), called a mekugi-ana. It is used to anchor the blade using a mekugi, a small bamboo pin that is inserted into another cavity in the Tsuka and through the mekugi-ana. Thus restricting the blade from slipping out. To remove the Tsuka you must remove the mekugi. Also, The swordsmith signature (mei) is placed on the nagako.

Decoration

Almost all blades are decorated, although not all blades are decorated on the visible part of the blade. Once the blade is cool, and the mud is scraped off, the blade has designs and grooves cut into it. One of the most important markings on the sword is performed here: the file markings. These are cut into the tang, or the hilt-section of the blade, where they will be covered by a hilt later. The tang is never supposed to be cleaned: doing this can cut the value of the sword in half or more. The purpose is to show how well the blade steel ages. A number of different types of file markings are used, including horizontal, slanted, and checked, known as ichi-monji, kosuji-chigai, suji-chigai, o-suji-chigai, katte-agari, shinogi-kiri-suji-chigai, taka-no-ha, and gyaku-taka-no-ha. A grid of marks, from raking the file diagonally both ways across the tang, is called higaki, whereas specialized 'full dress' file marks are called kesho-yasuri. Lastly, if the blade is very old, it may have been shaved instead of filed. This is called sensuki. While ornamental, these file marks also serve the purpose of providing an uneven surface which bites well into the 'tsuka', or the hilt which fits over it and is made from wood. It is this pressure fit for the most part that holds the tsuka in place during the strike, while the mekugi pin serves as a secondary method and a safety.

Some other marks on the blade are aesthetic: signatures and dedications written in kanji and engravings depicting gods, dragons, or other 'acceptable' beings, called horimono. Some are more practical, grooves for lightening and extra flex (as well as an intimidating sound, called tachikaze, when swung with force). Grooves come in wide (bo-hi), twin narrow (futasuji-hi), twin wide and narrow (bo-hi ni tsure-hi), short (koshi-hi), twin short (gomabushi), twin long with joined tips (shobu-hi), twin long with irregular breaks (kuichigai-hi), and halberd-style (naginata-hi).

The presence of a so-called "blood groove" or fuller does not in actuality allow blood to flow more freely from cuts made with the sword. It leads to no demonstrable difference in ease withdrawing a blade nor reduce the sucking sound that many people believe was the reason for including such a feature in commando knives in World War II. The grooves are analogous in structure to an I beam, lessening the weight of the sword yet keeping structural integrity and strength. Nowadays, they may be included for decorative purposes or as advertising gimmicks rather than for structural reasons.

Furthermore the grooves (always done on both sides of the blade) make a whistling sound when the sword is swung (the tachikaze). If the swordsman hears one whistle when swinging a grooved katana then that means that just one groove is making the whistle. Two whistles means that both the edge of the blade and a groove are making a whistle, and three whistles together (the blade edge and both grooves) would tell the swordsman that his blade is perfectly angled with the direction of the cut.

Because of the distinctive whistling sound of the grooves, it is said that Ninja did not carry swords with grooves (at least while going on stealth missions), because the distinctive whistling sound that comes with them would betray the Ninja's presence. (Ninja would often not use swords anyway, as they preferred garrotes and small blades to slit throats. Even when a sword was used, Ninja made their own swords as few could afford professional swordsmith's work.)

Polishing

When the rough blade is completed, the swordsmith turns the blade over to a polisher called a togishi, whose job it is to polish the steel of the blade to a glittering shine and sharpen the edge for battle. This takes hours for every inch of blade, and is painstaking work with different kinds of very fine stone. Early polishers used three types of stone, whereas a modern polisher generally uses seven. The modern high level of polish was not normally done before around 1600. It almost always takes longer than actually crafting the blade does, and a good polishing makes a blade look better, while a bad polishing makes the best of blades look like gunto. More importantly, an unschooled polisher can permanently ruin the blade geometry or wear the steel down to its core steel, both of which effectively destroy the sword's monetary, historic, artistic, and functional value.

There are two general styles of polishing: hadori and sashikomi. Hadori is modern (invented in the last 100 years) and involves a whitened hamon roughly following the actual hamon, and a darkened body to make the whitened hamon stand out. Hadori is likened to "makeup" that enhances the beauty of a face. Sashikomi is closer to the old styles of polish, and does not attempt to outline the hamon. It more readily reveals details of the actual hamon and crystalline structure compared to hadori.

One of the ways in which blades can be judged is by what this polishing reveals: the crystalline structure of the blade becomes quite visible, and the hamon (incorrectly known in English as the temper line, where the hard edge fades into the softer steel of the body) shows the unique nature of the sword. Each blade is distinct in its hamon and the grain (hada) of its steel. The hamon, which is determined primarily by how the clay is applied, is often used as a kind of signature of the smith, above and beyond his own signature, and each tradition of swordsmiths often has a particular style of hamon it prefers over all others. Hamon vary from straight to wavy to shaped like crabs or zigzags, and in their wandering they reveal important facts about the blade itself. A good polishing reveals what speed the edge was cooled at, from what temperature, and what the carbon content of the steel is. It does this by displaying either predominately nioi, which is a mix of extremely fine martensite with troostite (another type of tempered steel), or the larger martensite crystals called nie, which look like individual dot-like mirrors.

Furnishings

From here, the blade is passed on to a hilt-maker. Hilts vary in their exact nature depending on the era, but generally consist of the same general idea, with the variation being in the components used and in the wrapping style. The obvious part of the hilt consists of a metal or wooden grip called a tsuka, which can also be used to refer to the entire hilt. The cross guard, or tsuba, on Japanese swords (except for certain twentieth century sabers which emulate Western navies') is small and round, made of metal, and often very ornate. (see related article on Koshirae)

There is a pommel at the base known as a kashira, and there is often a decoration under the braided wrappings called a menuki. A bamboo peg called a mekugi is slipped through the tsuka and through the tang of the blade, using the hole called a mekugiana drilled in it. This anchors the blade securely into the hilt. To anchor the blade securely into the sheath it will soon have, the blade acquires a collar, or habaki, which extends an inch or so past the cross guard and keeps the blade from rattling.

The sheaths themselves are not an easy task. There are two types of sheaths, both of which require the same exacting work. One is the shira-saya, which is generally made of wood and considered the 'resting' sheath, used as a storage sheath. The other sheath is the more decorative or battle-worthy sheath which is usually called either a jindachi-zukuri or a buke-zukuri, depending on whether it was supposed to be suspended from the obi(belt) by straps when the sword is mounted in Tachi-Koshirae or thrust through the obi if mounted as katana-koshirae, respectively. Other types of mounting include the kyu-gunto, shin-gunto, and kai-gunto types for the twentieth-century military, but these swords were generally mass-produced and highly inferior, and few true Japanese swords are mounted in these styles.

Use

Technique

The katana is primarily a cutting weapon, or more specifically, a slicing one. However, the katana's moderate curve allows for effective thrusting as well.

The hilt of the katana is often held with two hands, though a fair amount of one-handed techniques exist. The left hand can clutch the katana in two different ways. Some practitioners, during times when the bokken was in greater use, closed the pinky finger upon itself, serving as a platform for the bottom of the tsuka to rest upon; this worked well with bokken, since the bottom of its tsuka would be flat. The ring, middle, and index fingers would wrap around the hilt in a more orthadox fashion. The second method for holding katana with the left hand was to grasp it as one would grasp any other hilt -- just above the pommel. The reason for this was because, with live blades, some katana featured sharp pommels, which could cause discomfort if held as previously stated.

The placement of the right hand was dictated by both the length of the tsuka and the length of the weilder's arm. The swordsman would outstretch his right arm, turning the underside of his forearm upwards. Then, he would place the bottom of the hilt against the elbow joint and bend his arm, bringing his hand to grasp the tsuka. The highest point on the tsuka -- from said position -- that can be grasped is then considered to be the proper placement of the right hand, for that specific swordsman.

For cutting, there was a specific technique called 'ten uchi.' Ten uchi refers to an organized motion made by arms and wrist, during a descending strike. As the sword is swung downwards, the elbow joint drastically extends at the last instant, popping the sword into place. This motion causes the swordsman's grip to twist slightly and if done correctly, is said to feel like 'wringing a towel.'

This motion itself caused the katana's blade to impact its target with sharp force, and is used to break initial resistance. From there, fluidly continuing along the motion wrought by 'ten uchi,' the arms would follow through with the stroke, dragging the sword through its target. Because the katana slices rather than chops, it is this 'dragging' which allows it to do maximum damage, and is thusly incorporated into the cutting technique. At full speed, the swing will appear to be full stroke, the katana passing through the targeted object. The segments of the swing are hardly visible, if at all.

Recapping -- assuming that the target is, for example, a human torso -- ten uchi will break the initial resistance suppled by shoulder muscles and the clavical. The follow through would continue the slicing motion, through whatever else it would encounter, until the blade inherently exited the body, due a combination of the motion and its curved shape.

For horizontal slashes, a similar concept is applied. However, the right hand is allowed, by some practitioners, to slide along the tsuka, closing the gap between the two hands. This allows for several more inches of reach, when swinging towards the opponent's right flank. The right side is more commonly targeted, due to the obstacle, which is the daisho -- situated on a samurai's left hip. Those sheaths, or the wakizashi, could hinder a cut or render it completely useless.

It is comparably difficult to apply ten uchi to an uppercut slash -- which can only be done, again, if attacking the opponent's right. Also, because rising attacks lack the same momentum as descending strokes, the affect is less potent. Often times, those cuts are made successful by drawing the edge along the target, more than anything else.

Without the use of proper technique, the katana's cutting power is more than halved. Also, improper technique has been known to damage the blade, on more than one occassion.

These is another set of specialized techniques for defense. The katana's razor-edge could only exist because of its extreme hardness. The edge was so hard, as a bi-product, that it chipped quite easily. As such, blocking an oncoming blow blade-to-blade was avoided at all costs. In fact, evasive body maneuvers was generally preferred over blade contact, on the whole. But, if such was impossible, the side or the back of the blade was used for defense by many styles, rather than the precious edge.

A popular method for defeating descending slashes was to simply beat the sword aside. As an enemy's blade raced downwards, a samurai could raise his at a shallow angle, and slap the oncoming katana's flank with the side of his own blade. This technique would bring the defender into a high-guard -- poised to strike -- as the attacker's sword would've been redirected, harmlessly falling to the side. The tables would be effectively turned.

In some instances, an unmbrella block -- positioning the blade overhead, diagonally (point towards the ground, pommel towards the sky)-- would create an effective shield between and attacker's descending strike and the defender. If the angle of the block was drastic enough, the curve of the katana's spine would cause the attacker's to slide along its counter and slide off to the side.

Horizontal attacks could be countered by voiding (repositioning the body, out of harms way) and beating the horizontal swing downwards, and effectively off-course for good measure. This could be done with a descending strike, aimed at the oncoming sword.

Thrusts were often beaten to the side.

Ultimately, there were numerous methods of attack, and defensive techniques to counteract all of them. However, something consistent with all of said methods -- the edge was never used to block.

Just about all forms of kenjutsu (the usage of the sword for combat) styles share the same five basic guards. They are as follows; chudan no kamae (middle guard), jodan no kamae (high guard), gedan no kamae (low guard) hasso (side guard), and waki no gamae (rear guard).

Testing of swords, called tameshigiri, was practiced on a variety of materials (including people) to test the sword's sharpness and also practice cutting technique. Considering the broader case of Japanese swords, rather than the specific case of the shinto katana, technique varies over time depending on the style of fighting prevalent in military operations of the time.

In certain eras, the sword becomes longer and is intended for use from horseback. At the same time, footmen may accompany a horseman and be armed with shorter katate-uchi at their side. This is a katana with a shortened length and handle, intended for one-handed fighting only, and is also called wakizashi or kodachi.

As armor and enemies changed over time, the shapes of blades changed from heavier profiles to lighter profiles, with different intentions for use in fighting. The heavier blades were fitted for heavier, slower, more powerful combat, while the lighter blades were suited for speed and accuracy.

The sword was mostly considered as a secondary weapon until the Kamakura period(1185-1333), used in the battlefield after the bow, or spear was no longer feasible. Then during Kamakura period the Tachi a predecesor of the katana became the primary weapon on the battlefield, used by cavalry mounted samurai. However, during the Edo period of Japan, Samurai went about on foot unarmored, and with much less combat being fought on horseback in open battlefields, and the need for an effective close quarter weapon resulted in samurai being armed with daisho.

Comparisons with swords of other cultures

The Japanese sword has, over its millennium of usage, developed a fearsome reputation and has been praised widely for its sharpness and effect on the battlefield. However, over the years and especially during the 20th century its reputation as a superior weapon has given rise to a number of inaccurate myths about its actual capabilities.It is very hard to compare the Katana to the swords of other cultures without providing an extensive amount of information about each individual type. As a result, it is necessary to give only an overview.

Because Japan was an iron-poor society, making a sword was an inherently expensive undertaking, and so the majority of swords made were of high quality. Europe, for example, also had superlative swordsmiths; Toledo steel swords from Spain are one example of legendary swords from outside Japan. However, the greater availability of iron made it practical to also produce low-cost, fair-quality weapons in large quantities. Where Europeans had the choice between expensive swords and cheap swords, Japanese had the choice between expensive swords, somewhat less expensive swords, or none at all.

The differences between the katana and certain other swords are due less to the limitations of their makers than to the requirements of their use. Attempting to establish the superiority of the one weapon over the other is ultimately meaningless without first defining the circumstances in which they are to be compared. Some European swords were designed for different modes of combat. The katana's sharpness makes it an excellent cutting weapon, but this is matched by the swords of other nations designed to cut. Katanas are capable of damaging Japanese armor to varying degrees. Older Koto era Shobu Zukuri type swords were designed when armor was prevalent and were generally slightly more curved and thick; consequenty they had relatively good armor penetration. As sword making moved onto the Shinto period the blades tended to become thinner and slightly less curved for use against unarmored opponents; nevertheless weapons such as the yari were favored for armored opponents because sword attacks sometimes did not penetrate deeply enough to be fatal. Even today Shinkendo masters perform a helmet cutting ceremony. However it is worth noting that European swords of a similar length and weight to the katana were virtually useless against European plate armour and chainmail. In European swordsmanship the correct technique in against mail was to thrust through it, and against plate, to take the sword by the blade in the left hand, and thrust at the gaps in the armor.

Katanas were produced with a forging method that resulted in a very hard Martensite edge with a soft but flexible Pearlite core and spine. The majority of the swords of other cultures were of an even hardness throughout the blade, although some Chinese, European and Arabic swords also had a hard edge and a soft core. Most notable among these are the Chinese Dao, The Damascus made Scimitar and European blades of Type X and XI on the Oakeshott typology.[2] [3]. Both types of construction had their advantages and disadvantages; a harder edge generally stays sharp longer, but also is more prone to chipping, while a softer edge loses its sharpness and becomes gouged more easily, but is more resistant to fractures. In a katana, the softer, tougher core provides support for the hard edge, and so makes the entire sword more resistant to breakage while retaining the benefits of a hard edge, although the edge itself remains brittler than a softer one. In tests a traditionally forged katana was able to shatter a .45ACP round from a handgun without sustaining damage, and managed to withstand seven direct hits from an M2 heavy-machine gun and its .50 BMG armor-piercing bullets before shattering. The same blade also proved impenetrable to an iron-cutting machine. How the swords of other cultures would do in such a test is not known, but it is worth remembering that trick-shooters have split bullets (albeit much smaller, softer and slower ones) off of knives for a very long time, and that the M2 was used in WWII as a anti-tank weapon. [4] [5]

Many sword types from the very beginning of the history of the sword, through the medieval period and the renaissance to the 20th century, were designed for the same combat modes as Japanese ones, fighting against lightly-armored or unarmored men on foot. Styles that relied on a single longsword for both offense and defense were well known outside of Japan as well - see e.g. Joachim Meyer's Fechtbuch[6] - and disparities in weight have been greatly exaggerated; both katanas and other longswords weighed between 1.0 and 1.5 kilograms (2-3 pounds).

References

note katana and their relationt to other swords has sparked a number of arguments on the Dungeons&dragons messidge bords

See also

Some famous katana smiths

Famous historic katana users

- Ashikaga Yoshiteru

- Tsukahara Bokuden

- Iizasa Ienao

- Miyamoto Musashi

- Sasaki Kojiro

- Okita Soji

- Saito Hajime

- Hattori Hanzo

- Saigo Takamori

- Toshiro Mifune - actor

- NKHC

- Kawakami Gensai

- Akechi Mitsuhide

Recommended reading

- Irvine, Gregory. The Japanese Sword: The Soul of the Samurai. London: V&A Publications, 2000.

- Kapp, Leon. The Craft of the Japanese Sword. Kodansha Intl. Ltd., 1987.

- Perrin, Noel. Giving Up the Gun: Japan's Reversion to the Sword, 1543-1879. Boston: David R. Godine, 1979.

- Robinson, H. Russell. Japanese Arms and Armor. New York: Crown Publishers Inc., 1969.

- Sinclaire, Clive. Samurai: The Weapons and Spirit of the Japanese Warrior

- Yumoto, John M. The Samurai Sword: A Handbook. Boston: Tuttle Publishing, 1958.

External links

- Japanese Martial Arts Center

- Video: The Art of Japanese Swordsmanship

- THE JAPANESE SWORD INDEX

- Japanese Swords Arms & Armor --Authentic Antique Japanese Swords

- Authentic Japanese Sword Store

- Japanese Sword and Fitting Aoi-Art.com

- Sword Terminology

- Japanese sword school

- Japanese Sword Glossary

- Modern Japanese Sword Smiths, Polishers and more

- YouTube video showing katana splitting a bullet