Model rocket

Model rocketry is a hobby similar to building model airplanes. In the hobby today, there are two distinct areas of rocket activity: amateur (or experimental) rocketry, and model rocketry (including high powered rocketry).

Model and High Power Rocketry

Model rocketry and high power rocketry involve professionally-manufactured solid-fuel or hybrid liquid/solid fuel rocket motors. Since these motors are professionally designed and constructed, they are far safer than motors produced by individuals for use in amateur or experimental rocketry. The motors also are tested and certified by the National Association of Rocketry or the Tripoli Rocketry Association and come in standardized sizes and powers.

Model Rocketry

According to the National Association of Rocketry safety code, model rockets are constructed of paper, wood, plastic and other lightweight materials. The code also provides guidlines for motor use, launch site selection, launch methods, launcher placement, recovery system design and deployment and more. Since the early 1960's, a copy of the Model Rocket Safety Code has been provided with most model rocket kits and motors. Model rocketry is a very safe hobby, provided precautions are taken as given in the safety code.

Model rocketry is enjoyed by many different levels of hobbyist, from grade-school children launching 3 inch (75 mm) tall models in the baseball field, to teams of adults launching 200 pound (100 kg) behemoths thousands of feet into the air. Model rocketry is often credited as the most significant source of inspiration for children who eventually become scientists and engineers. See National Association of Rocketry (NAR).

The History of Model Rocketry

The model rocket, and more importantly, the model rocket engine, was designed in 1954 by Orville Carlisle, a licensed pyrotechnics expert, and his brother Robert, a model airplane enthusiast. They originally designed the engine and rocket for Robert to use in lectures on the principles of rocket powered flight. But then Orville read articles written in Popular Mechanics by G. Harry Stine about the safety problems associated with young people trying to make their own rocket engines. With the launch of Sputnik, many young people were trying to build their own rocket engines, often with tragic results. The Carlisles realized their engine design could be marketed and provide a safe outlet for a new hobby. They sent samples to Mr. Stine in January, 1957. Stine, a range safety officer at White Sands Missile Range, built and flew the models, and then devised a safety code for the activity based on his experience at the range.

The National Association of Rocketry was founded in 1957 to help promote not only the hobby, but to promote the safety of the activities related to model rocketry.

Model Rocket Companies

Vernon Estes founded Estes Industries in 1958 in Denver, Colorado, and developed a high speed automated machine for manufacturing solid model rocket motors. The machine, nicknamed "Mabel", enabled Estes to market low cost motors with great reliability (est. 1 in 3,000 failed). Subsequently, model rocket kits became very popular, with Estes dominating the market. Estes moved his company to Penrose, Colorado in 1960, and it continues to operate there today as a subsidiary of Damon Corporation.

Competitors like Centuri and Cox came and went during the 60's, 70's and 80's, but Estes continued to control the market, offering discounts to schools and clubs like Boy Scouts of America to help grow the hobby. In recent years, companies like Quest have taken a small portion of the market, but Estes continues to be the main source of rockets, motors, and launch equipment for the low powered rocketry hobby today.

In the high powered arena, which began in the mid-80's with the availability of J, K and L class motors, a number of companies have shared the market. By the early 1990's, Aerotech International, LOC/Precision, and Public Missiles had taken up leadership positions, while a host of engine manufacturers provided ever larger engines, at much higher costs. Companies like Aerotech, Vulcan, and Kosdon were widely popular at launches during this time as high powered rockets routinely broke Mach 1 and reached heights over 10,000 ft.

Engine reliability became a significant issue though, with "CATO"s, or catastrophic failures, occuring relatively frequently (est. 1 in 20) when motors of L class or higher were fired. At costs exceeding $300 per motor, the need to find an alternative was apparent. In the late 1990's, reusable motors (metal sleeves with screwed on end caps and filled with cast propellant slugs) became a popular way to reduce the price of launches and dominate the market today. At this time (2006) single use motors above G class are quite rare, and many are collectables. Aerotech, Dr. Rocket, Ellis Mountain, and Loki Motorworks provide the majority of reloadable systems today.

Model rockets of special interest

Model rockets equipped with the Astrocam or Snapshot film camera or the Oracle digital camera, or with homebuilt equivalents, can be used to take aerial photographs. Model rockets with electronic altimeters can report and or record electronic data such as maximum speed, acceleration, and altitude.

Model rocketeers often experiment with rocket sizes, shapes, payloads, multistage rockets, and recovery methods. Some rocketeers build scale models of larger rockets, space launchers, or missiles.

High Power Rocketry (HPR)

As with low power model rockets, high power rockets are also constructed from lightweight materials, but instead of paper, plastic, and wood, usually fiberglass, composites, and aluminum are needed to withstand the higher stresses during flight which often exceeds Mach 1 (~700 mph) and over 10,000 ft altitude.

High power model rockets are propelled by larger motors ranging from class H to O and can be up to 40 feet tall. Their motors are almost always reloadable rather than single-use in order to reduce cost. Recovery and/or multi-stage ignition may be initiated by small on-board computers, which use an altimeter or accelerometer for detecting when to ignite engines or deploy parachutes.

High powered model rockets can carry large payloads, including cameras and instrumentation such as GPS units, and are not much different from their military counterparts. However, unlike military rockets, high-powered model rockets generally do not contain any type of guidance system.

Since the September 11, 2001 attacks, high powered model rocketry in the United States has been even more carefully monitored by the government. Engine vendors and participants must be licensed, and all high-power flights require FAA notification.[citation needed]

Recovery

Model and high-power rockets are designed to be safely recovered and flown repeatedly. The most common recovery methods are parachute and streamer.

Tumble Recovery

The simplest approach, and one only appropriate for small rockets or rockets with a large cross-sectional area, is to have the rocket tumble back to earth. Any rocket which will enter a stable, ballistic trajectory as it falls is not safe to use with tumble recovery.

Parachute/Streamer

The approach used most often in small model rockets, is to use the ejection charge of the motor (see below) to deploy, or push out, the parachute or streamer. Air resistance retards the rocket's fall.

Glide Recovery

In glide recovery, the ejection charge either deploys an airfoil (wing) or separates a glider from the motor. If properly trimmed, the rocket/glider will enter a spiral glide and return safely. In some cases, radio-controlled rocket gliders are flown back to the earth by a pilot in much the way as R/C model airplanes are flown.

Helicopter Recovery

The ejection charge, through one of several methods, deploys helicopter-style blades and the rocket auto-rotates back to earth.

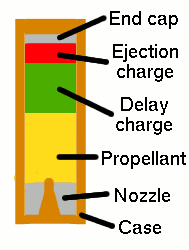

Model Rocket Motors

Most small model rocket motors are single-use engines, with cardboard bodies and lightweight molded ceramic nozzles, ranging in power class from 1/8-A to E. They contain a black powder propellant.

Larger rocket motors are also available, using composite propellants made of ammonium perchlorate and a rubbery binder substance contained in a hard plastic case. These motors range in impulse from the B to the O range. Composite motors produce more impulse per unit weight than do black powder motors.

Reloadable motors are also available. These are commercially-produced motors requiring the user to put propellant grains, o-rings and washers (to contain the expanding gases), delay grains and ejection charges into special non-shattering aluminum motor casings with screw-on or snap-in ends (closures). The advantage of a reloadable motor is the cost: because the main casing is reusable, reloads cost significantly less than single-use motors of the same impulse. Reloadable motors are available from D through O class.

Motors are electrically ignited with a short length of pyrogen-coated nichrome wire pushed into the nozzle and held in place with flameproof wadding, a plastic plug or masking tape. On top of the propellant is a tracking delay charge which produces smoke but essentially no thrust as the rocket slows down and arcs over. When the delay charge has burned through, it ignites an ejection charge, which is used to deploy the recovery system.

What the Numbers Mean

Model rocket motors produced by companies like Estes Industries and Quest Aerospace are stamped with a code (such as A10-3T or B6-4) that tells several things about of motor.

Motors are commercially available in many sizes. The Quest Micro Maxx engines are the smallest at a diameter of 6mm. The company Apogee made 10.5mm micro motors, but those were discontinued in 2001. Estes then comes in with "T" (Tiny) motors that are 13 mm in diameter by 45 mm long, while standard A, B and C motors are 18 mm in diameter by 70 mm long. Larger C, D, and E class black powder motors are also available; they are 24 mm in diameter and either 70 (C and D motors) or 95 mm long (E motors). Some motors, such as F and G single-use motors are 29mm in diameter. High-power motors (usually reloadable) are available in 38mm, 54mm, 75mm, and 98mm diameters.

The Letter

The letter at the beginning of the code indicates the motor's total impulse range (commonly measured in newton-seconds). Each letter in successive alphabetical order has up to twice the power of the letter preceding it. This does not mean that a given "C" motor has twice the total impulse of a given "B" motor, only that C motors are in the 5.01-10.0 N-s range while "B" motors are in the 2.51-5.0 N-S range. The designations "1/4 A" and "1/2 A" are also used. For a more complete discussion of the letter codes, see Model rocket motor classification.

For instance, a B6-4 motor from Estes Corporation has a total impulse rating of 5.0 N-s. A C6-3 motor from Quest Industries has a total impulse of 8.5 N-s. [1]

The First Number

The number that comes after the letter indicates the motor's average thrust, measured in newtons. A higher thrust will result in higher liftoff acceleration, and can be used to launch a heavier model. Within the same letter class, a higher average thrust also implies a shorter burn time (e.g., a B4 motor will burn longer than a B6).

The Last Number

The last number is the delay in seconds between the end of the thrust phase and ignition of the ejection charge. Black Powder Motors that end in a zero have no delay or ejection charge. Such motors are typically used as first-stage motors in multi-stage rockets as the lack of delay element and cap permit burning material to move forward and ignite an upper-stage motor.

A "P" indicates that the motor is "plugged". In this case, there is no ejection charge, but a cap is in place. A plugged motor can only be used in rockets which do not need to deploy a standard recovery system such as small rockets which tumble or R/C glider rockets.

Reloadable Motors

Reloadable motors are specified in the same manner as model rocket single-use motors as described above. However, they have an additional designation which specifies both the diameter and length of the motor casing in the form of diameter/length. A reload designed for a 29mm diameter case with a 60mm length carries the designation 29/60 in addition to its impulse specification.

Safety

Model rocketry is a safe and widespread hobby. Individuals such as G Harry Stine and Vernon Estes helped ensure this by developing and publishing the National Association of Rocketry Model Rocket Safety Code, and by commercially producing safe, professionally-designed and manufactured model rocket motors.

Controversy in the U.S.

Both amateur and model rocketry have come under controversy in the United States following the terrorist attacks on New York and Washington D.C., as federal and state authorities allege that model rockets can be modified to act as weapons.

Authorities argue that all members of the hobby should have to be licensed and their purchases recorded and reported to federal agencies. Critics of such policies, particularly those involved in the hobby itself, argue that while building model rockets capable of going great distances is a relatively simple feat, guidance systems are exceedingly difficult to design and expensive to implement.

The NAR and Tripoli continue to pursue litigation against the BATFE in the matter.

References:

- ^ National Association of Rocketry web site: http://nar.org/SandT/NARenglist.shtml

See also

External links

- The National Association of Rocketry (NAR), one of the oldest model rocket clubs in the world

- The Tripoli Rocketry Association

- Canadian Association of Rocketry

- United Kingdom Rocketry Association

- Interessengemeinschaft Modellraketen - IMR (rocketry organization for Germany/Austria/Switzerland)

- Dutch Federation for Rocket Research, the oldest European association

- European Model Rocketry